The L298N and L293D motor drivers are two well-liked options when it comes to motor control in your DIY projects. These gadgets make it easy to control motors, but they also differ in a few key ways that make them useful in various situations. To assist you choose which one is best for your project, we'll compare the L298N and L293D in this blog post.

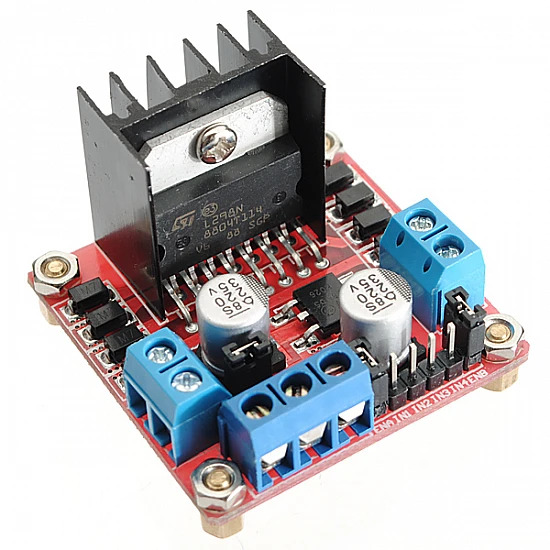

L298N Motor Driver

Pros:

- Higher Current Handling: The L298N can handle higher currents, making it suitable for driving larger motors.

- Dual H-Bridge Configuration: It has a dual H-bridge design, allowing you to control the direction and speed of two motors independently.

- Built-in Diodes: Integrated flyback diodes protect against back EMF, simplifying your circuit design.

Cons:

- Higher Voltage Requirements: It typically requires a higher input voltage, which may not be suitable for low-voltage applications.

- Larger Package: The L298N comes in a larger package, taking up more space on your project.

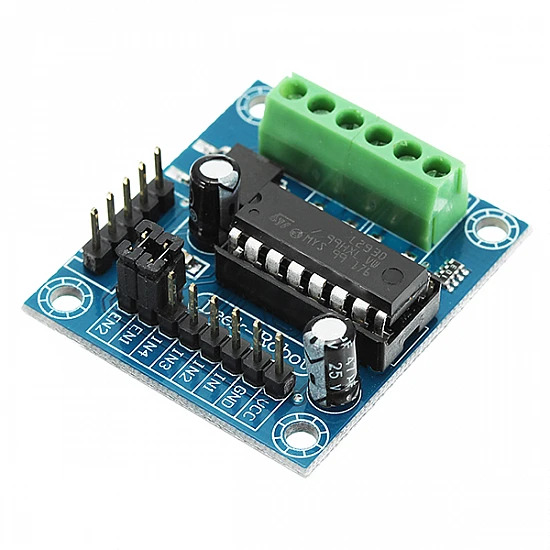

L293D Motor Driver

Pros:

- Lower Voltage Operation: The L293D can work with lower input voltages, making it ideal for battery-powered projects.

- Smaller Package: It comes in a smaller and more compact package, which is beneficial when space is a concern.

- Affordable: L293D is often more affordable, which can be a deciding factor for budget-conscious projects.

Cons:

- Lower Current Handling: It has lower current ratings compared to the L298N, so it's better suited for smaller motors.

- Single H-Bridge Design: The L293D can control one motor per IC, so you may need multiple ICs for multi-motor applications.

Choosing the Right Motor Driver

The choice between the L298N and L293D motor drivers ultimately depends on your project's requirements. Here are some guidelines to help you decide:

L298N: Select this motor driver if you have room for a larger module and need to drive larger motors at higher currents. It works great for demanding applications like automation and robotics.

L293D: Choose the L293D if you require a cost-effective solution for smaller applications, have space restrictions, or are working with lower-voltage motors. Smaller robotics and electronics projects frequently use it.

In conclusion, the L298N and L293D motor drivers each fill a specific purpose in the field of motor control. To select the best decision, consider the requirements of your project, including budget, motor size, and voltage. You may easily incorporate both drivers into your upcoming motor-driven project because they are both accessible and simple to utilize.

Leave a Comment